HBV-SYSTEMS | HBV-CEILINGS

HBV ceilings in new buildings can be built in most various ways:

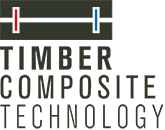

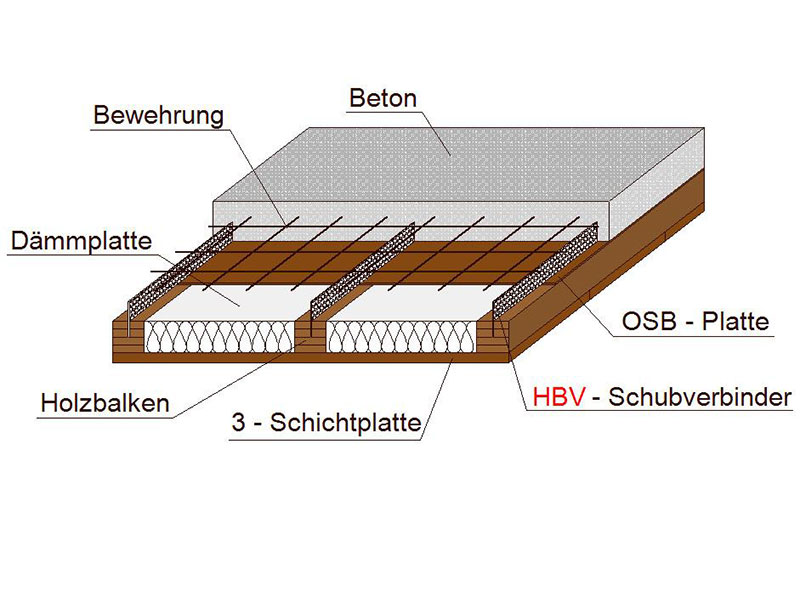

HBV ACOUSTIC CEILING

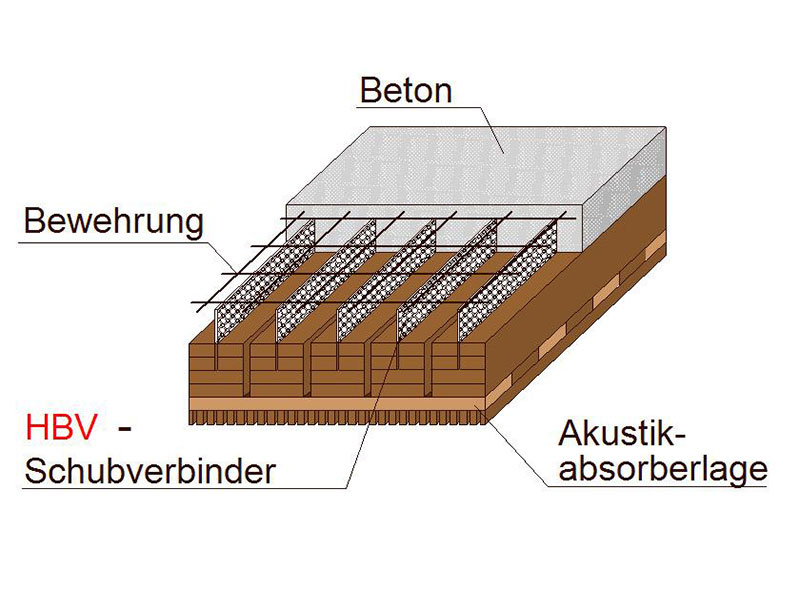

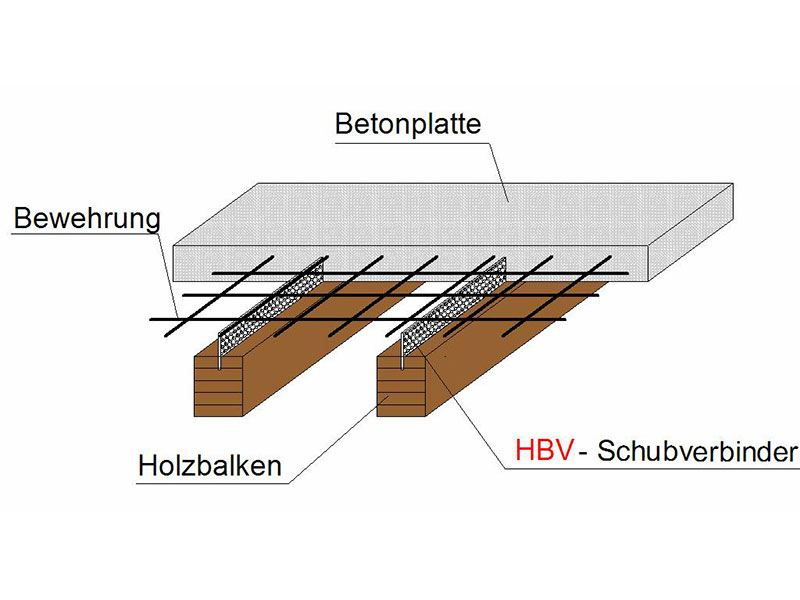

HBV BEAMED CEILING

HBV BOX BEAM CEILING

HBV BOX CEILING

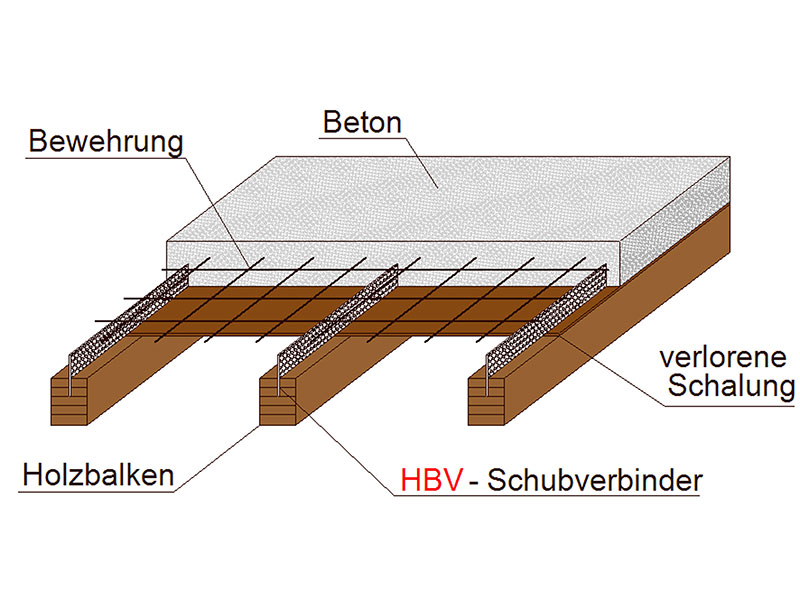

HBV SLAB CEILING

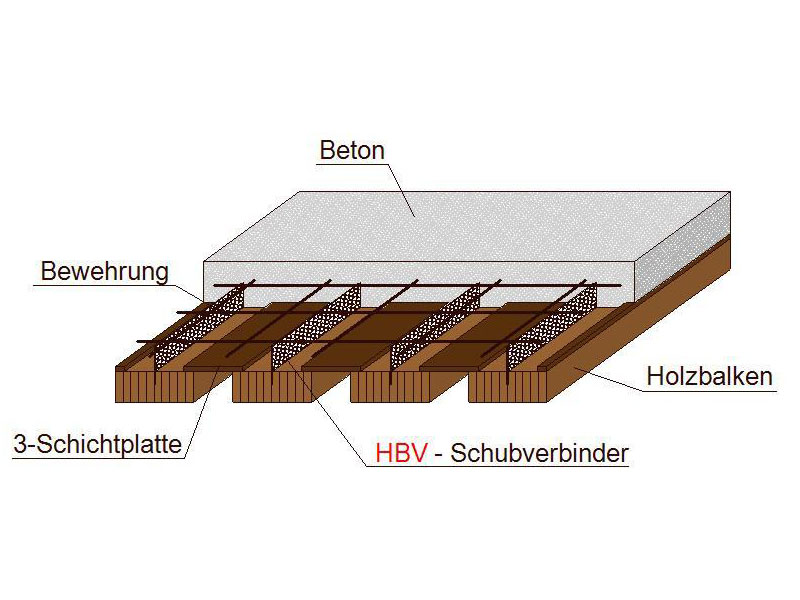

HBV RIBBED SLAB

HBV VARIO CEILING

Because ceilings, walls as well as roofs can be realized with HBV systems, a module house is also possible. This satisfies through its short construction time as well as the high grade of prefabrication and an especially economic modular construction.